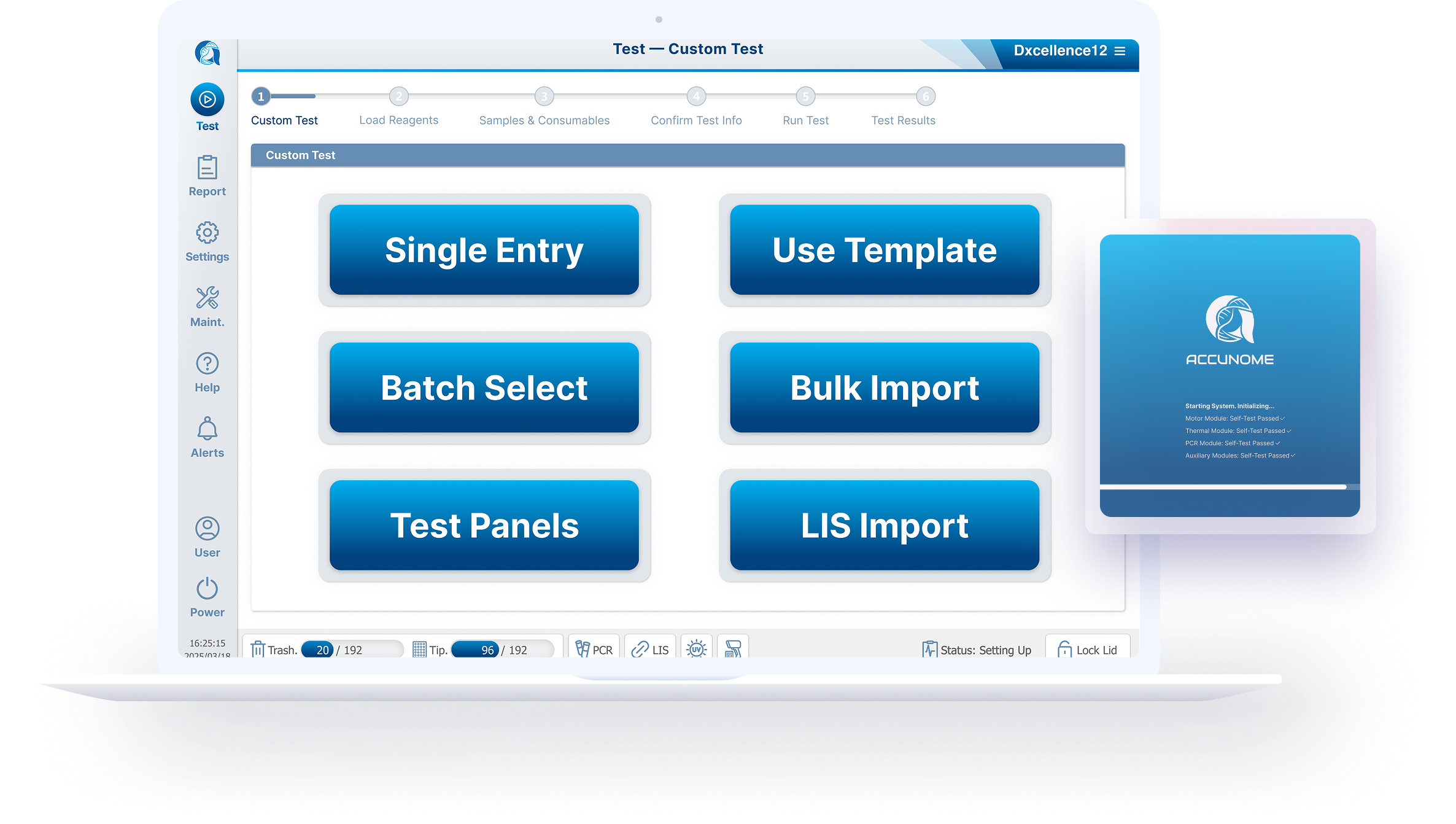

Accunome Science - DXcellence12

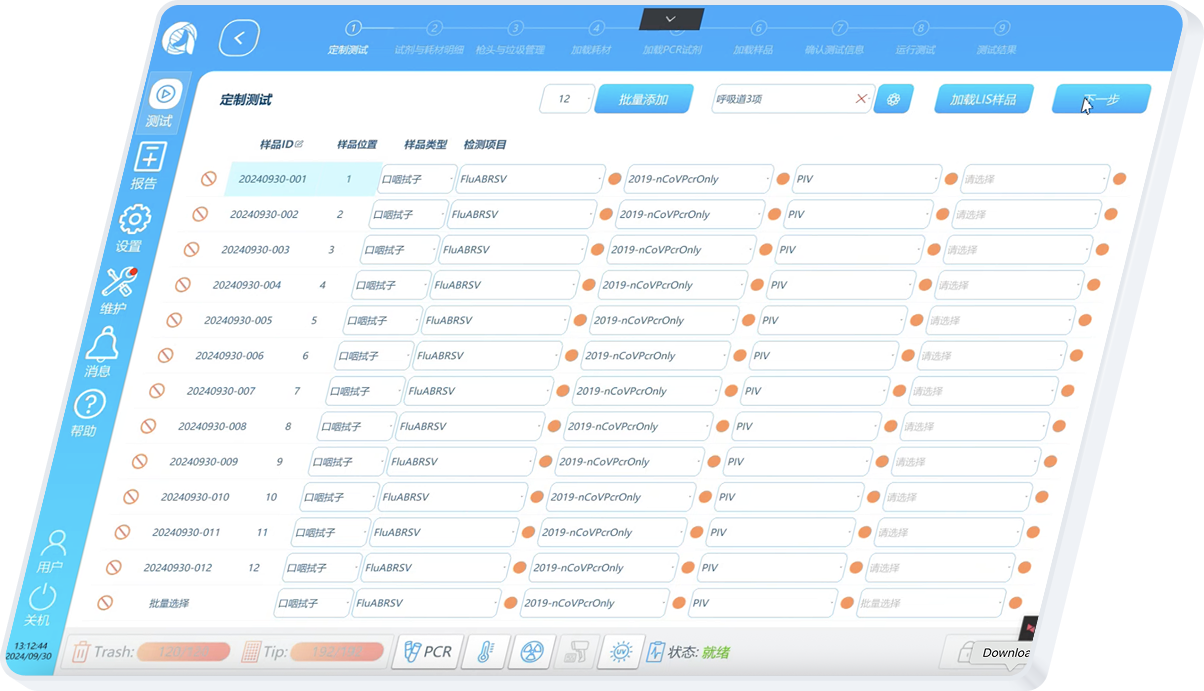

Designing a trustworthy, intuitive Custom Testing experience for a regulated molecular diagnostics platform. Transforming complex, error‑prone workflows into a visual, efficient, and compliant system used in real laboratories.

-

Company: Accunome Science

Product: DXcellence12 — Automated Molecular Diagnostics Platform

Users: Experimenter, Researcher, Scientist, Lab technician/technologist, Lab assistant

Environment: Regulated healthcare (IVD industry, compliance‑driven)Accunome Science, founded in San Diego (U.S.), was ranked as one of “The Top 50 Most Promising Startups” by Silicon Valley Media The Information.

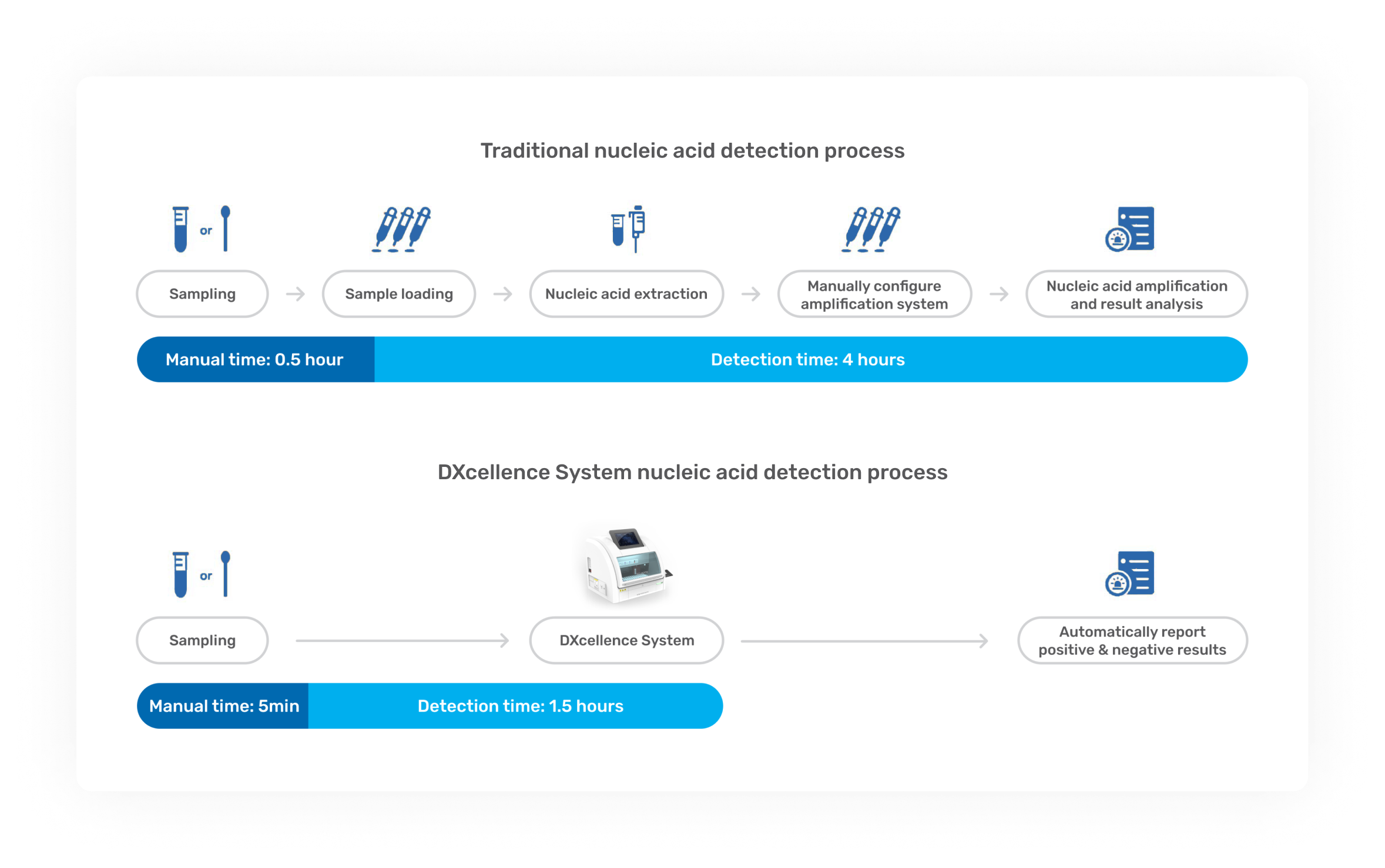

DXcellence12 is a fully automated molecular diagnostics platform that eliminates manual steps common in traditional nucleic acid testing, delivering a true “sample-in, result-out” workflow under strict regulatory and operational requirements. The software experience is as critical as the instrument itself: errors can directly affect patient outcomes, laboratory efficiency, and audit risk. -

I led end‑to‑end product design and UX strategy, spanning:

User research & field studies (labs, hospitals)

Workflow & systems design for complex B2B SaaS

Interaction design & high‑fidelity prototyping

Design system & visual language evolution

Stakeholder alignment (Product, Engineering, Sales, Regulatory, CEO)

Partner‑facing design (bioMérieux)

Usability testing, iteration, and implementation review

I owned the problem framing → solution definition → validation → delivery loop.

-

A High‑Risk, High‑Cognitive‑Load Workflow

The original table‑based Custom Testing UI required users to:

Configure samples across multiple fragmented screens

Mentally map tables to physical well positions

Manually manage batch logic, panels, and individual assays

Key pain points:

Error‑prone configuration under time pressure

Poor scalability for mixed batch scenarios

Low confidence and high cognitive load

Difficult onboarding for new lab staff

Why This Project Needed Strong Design Leadership

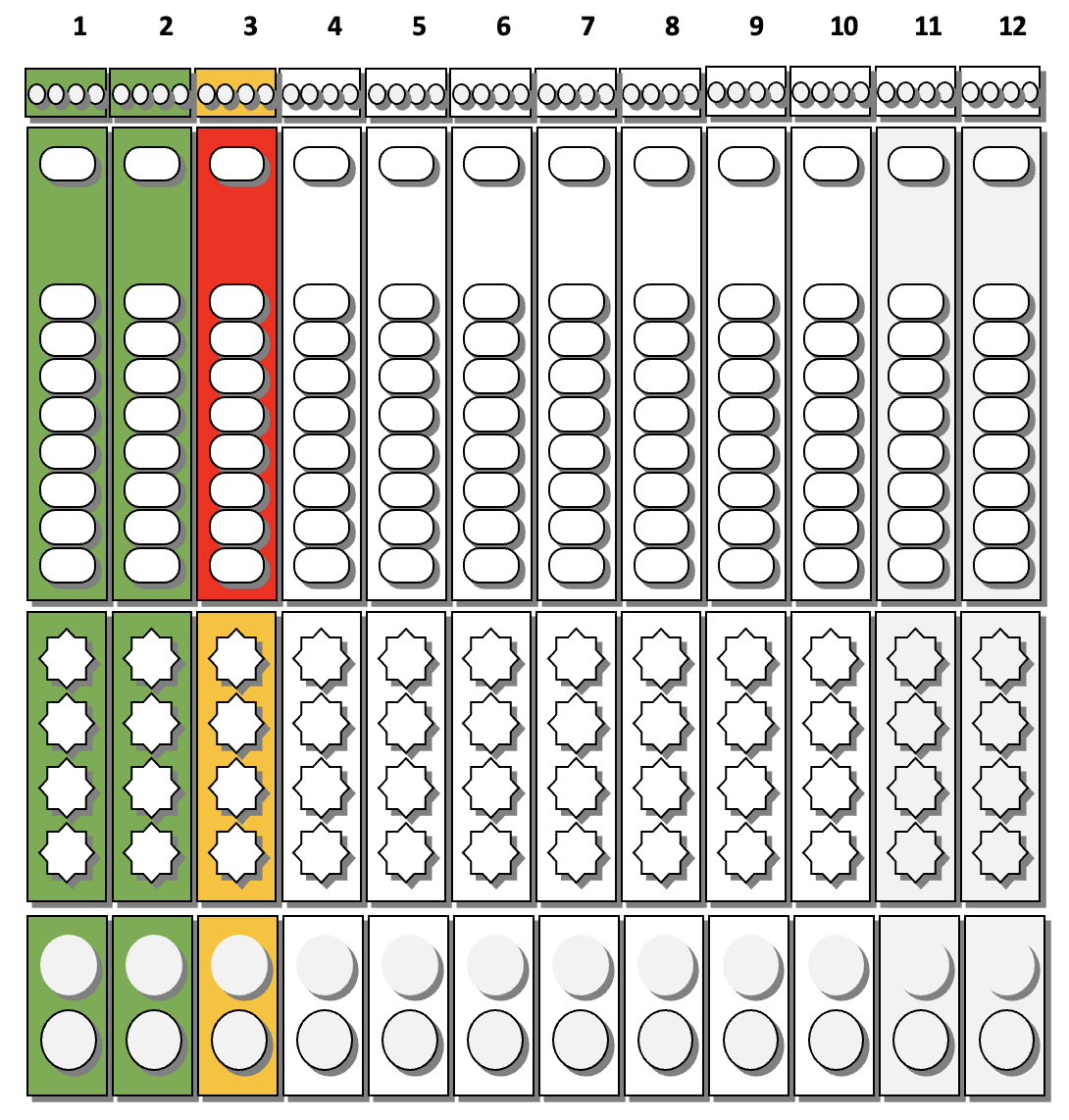

Custom Testing is the core, revenue‑critical workflow of DXcellence12.

DXcellence12's key value proposition: Flexible and Versatile.

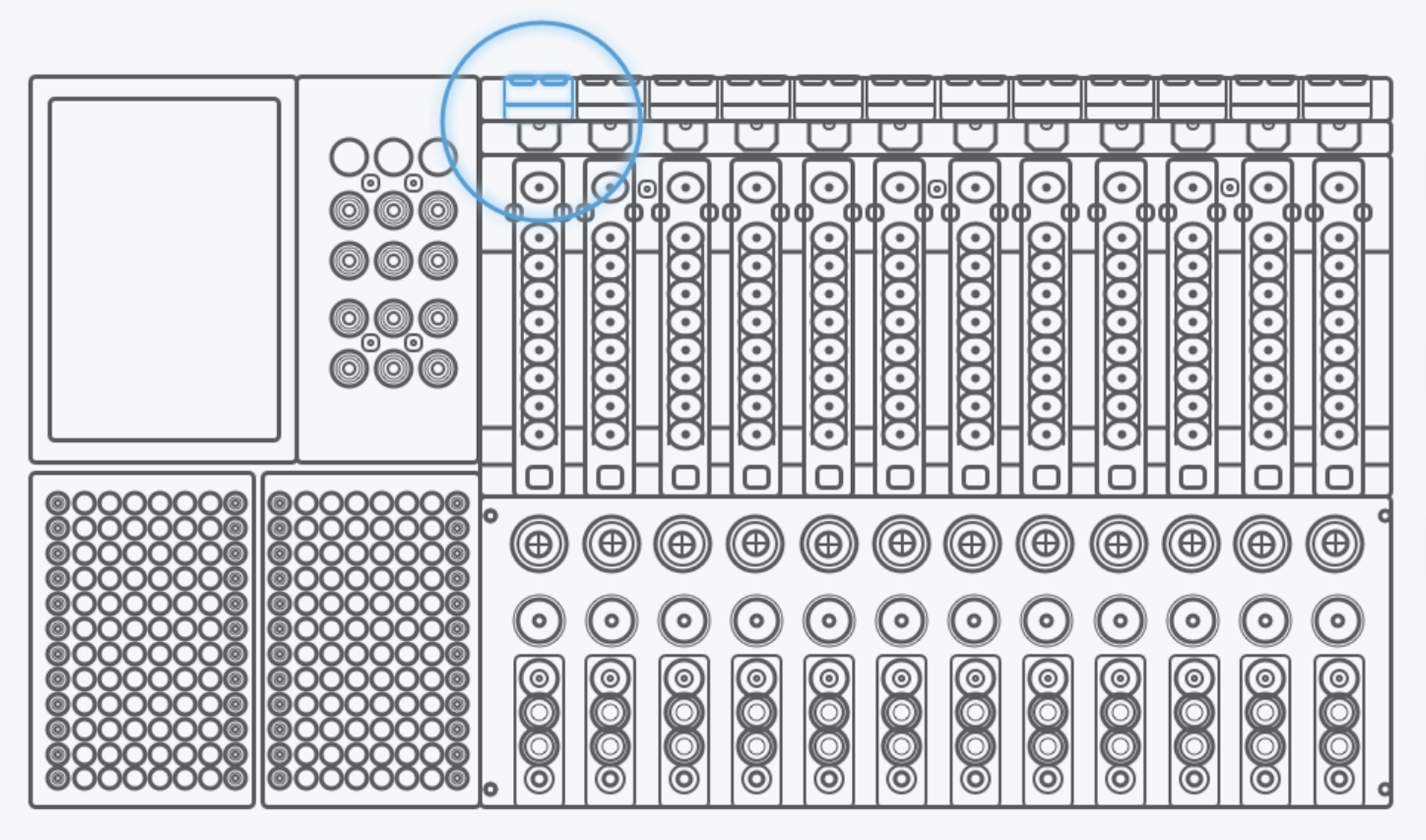

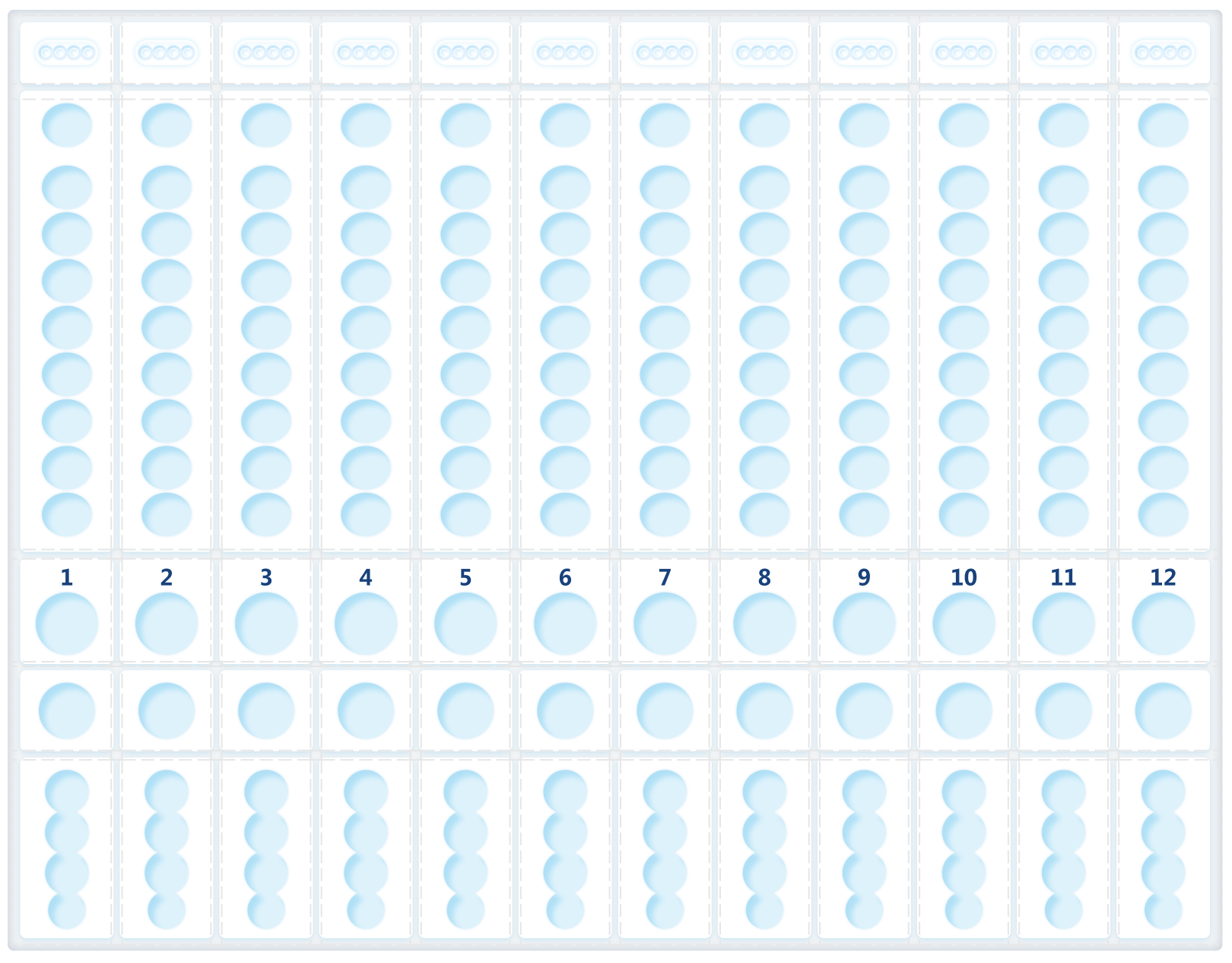

Allows Mixture of Different Types and Tests: Ability to customize up to 12 samples × 4 test targets with cross-contamination prevention.It directly affects accuracy, efficiency, adoption, and regulatory risk.

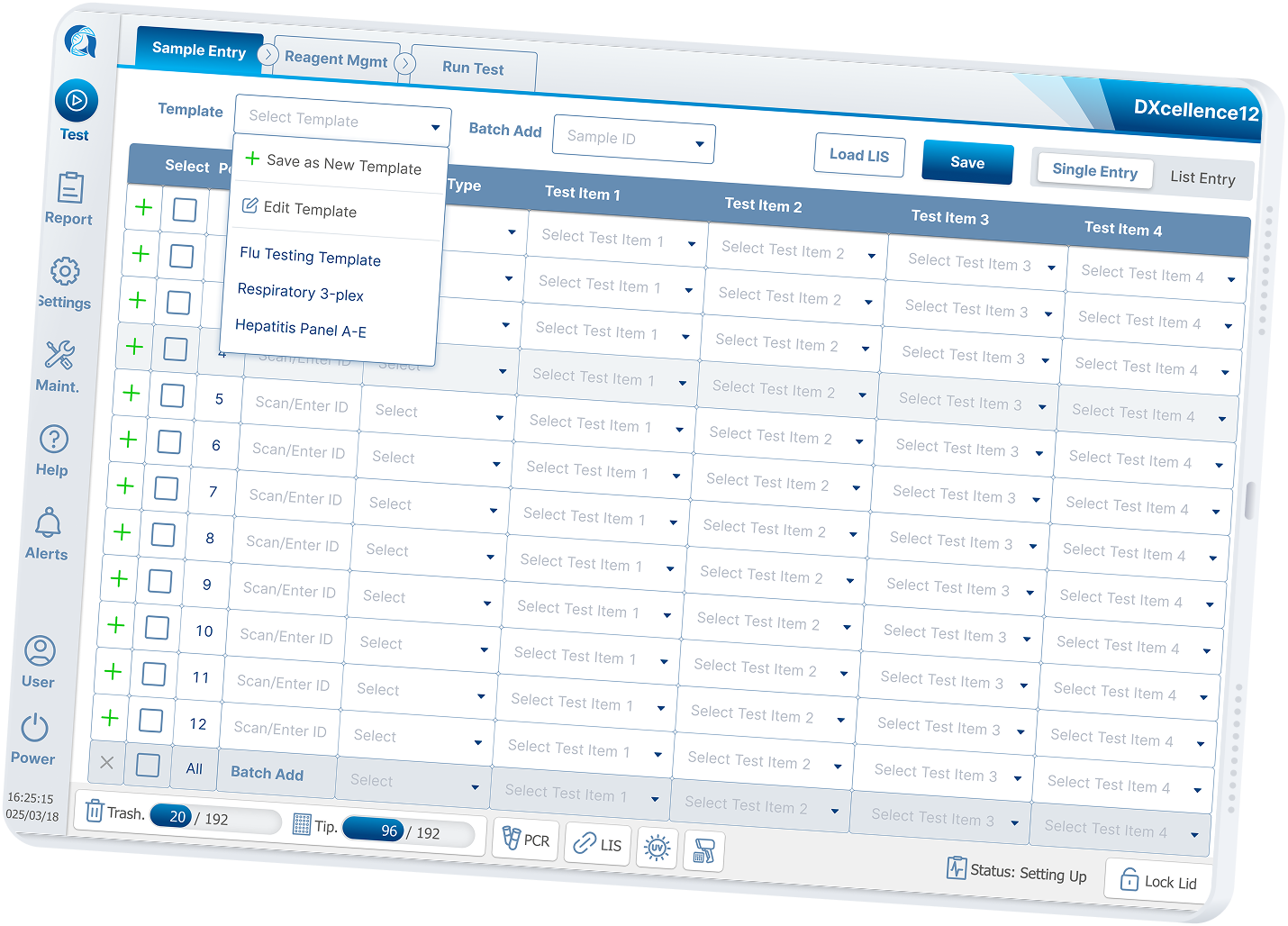

Before redesign, the experience was engineer‑built, table‑driven: a single view containing 48+ Excel‑like input cells. Users were forced to mentally map software rows and columns to the physical sample wells, while under time pressure.

High cognitive load

Frequent configuration errors

Steep learning curve for new technicians

Growing user frustration and complaints

This was not a visual problem. It was also a systemic UX and trust problem.

My Role: Owning the Problem End‑to‑End

I did not inherit a clear brief or roadmap item. I proactively drove the initiative:

Identified Custom Testing as a high-risk, high-impact workflow

Initiated cross‑functional alignment with Product, Engineering, Sales, Scientists, and CEO

Designed and led the full research and validation process

Carried insights through interaction design, iteration, and delivery

I pushed it forward and sustained momentum.

Research & Discovery

Multi‑Layered Research Approach: I combined qualitative, quantitative, and field‑based research.

Key Usage Scenarios Identified

Small labs (single machine)

Custom Testing is used differently every run

High need for flexibility and per‑sample control

Users actively configure tests each time

Large labs / hospitals (multiple machines)

High throughput, repetitive testing

Primary value is automation, speed, and consistency

Strong need of reusing configurations at scale

These distinct mental models shaped every design decision.

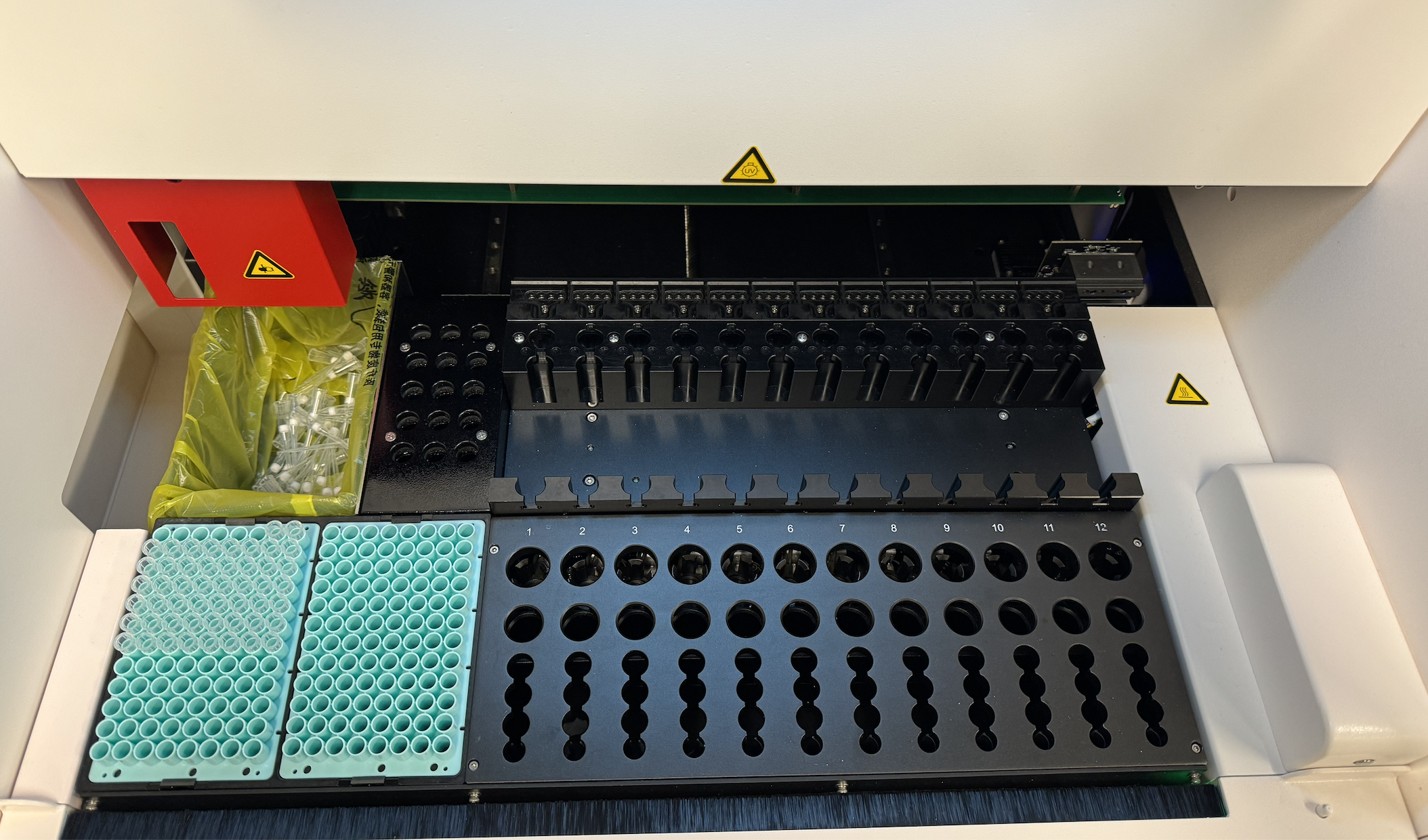

Direct immersion

Observed DXcellence12 usage in real lab environments

Personally operated the physical instrument

Reviewed real configuration errors and failure cases

User & Stakeholder Research

Interviewed lab technicians, lab directors, hospital IT

Designed structured questionnaires

Led Sales and Product teams into hospitals to collect firsthand feedback

This ensured insight was grounded in actual behavior, not assumptions.

Synthesizing the Real Problem

Through research, a pattern emerged:

Users think spatially, not tabularly

Batch efficiency and individual control must coexist

Software-hardware mental translation was the cause of error

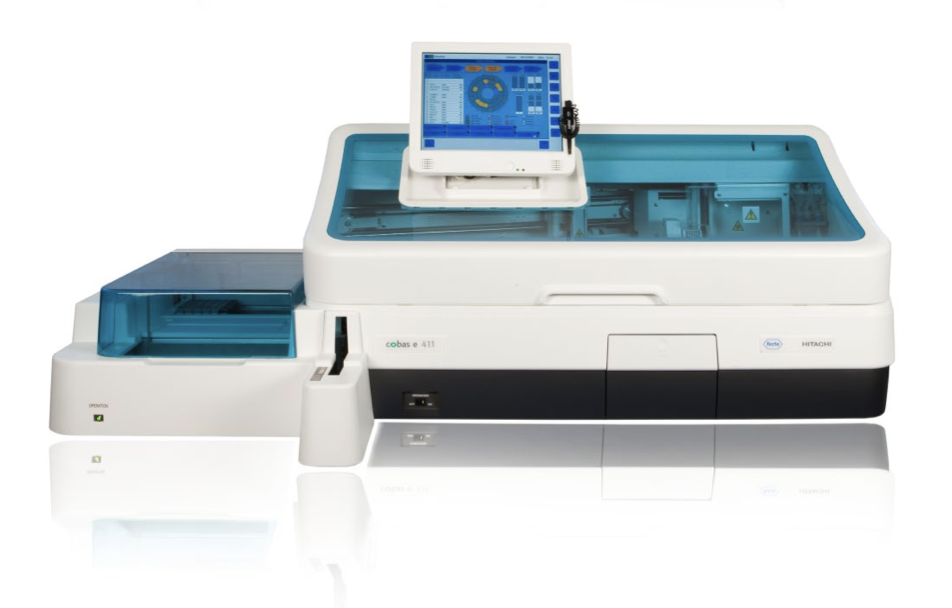

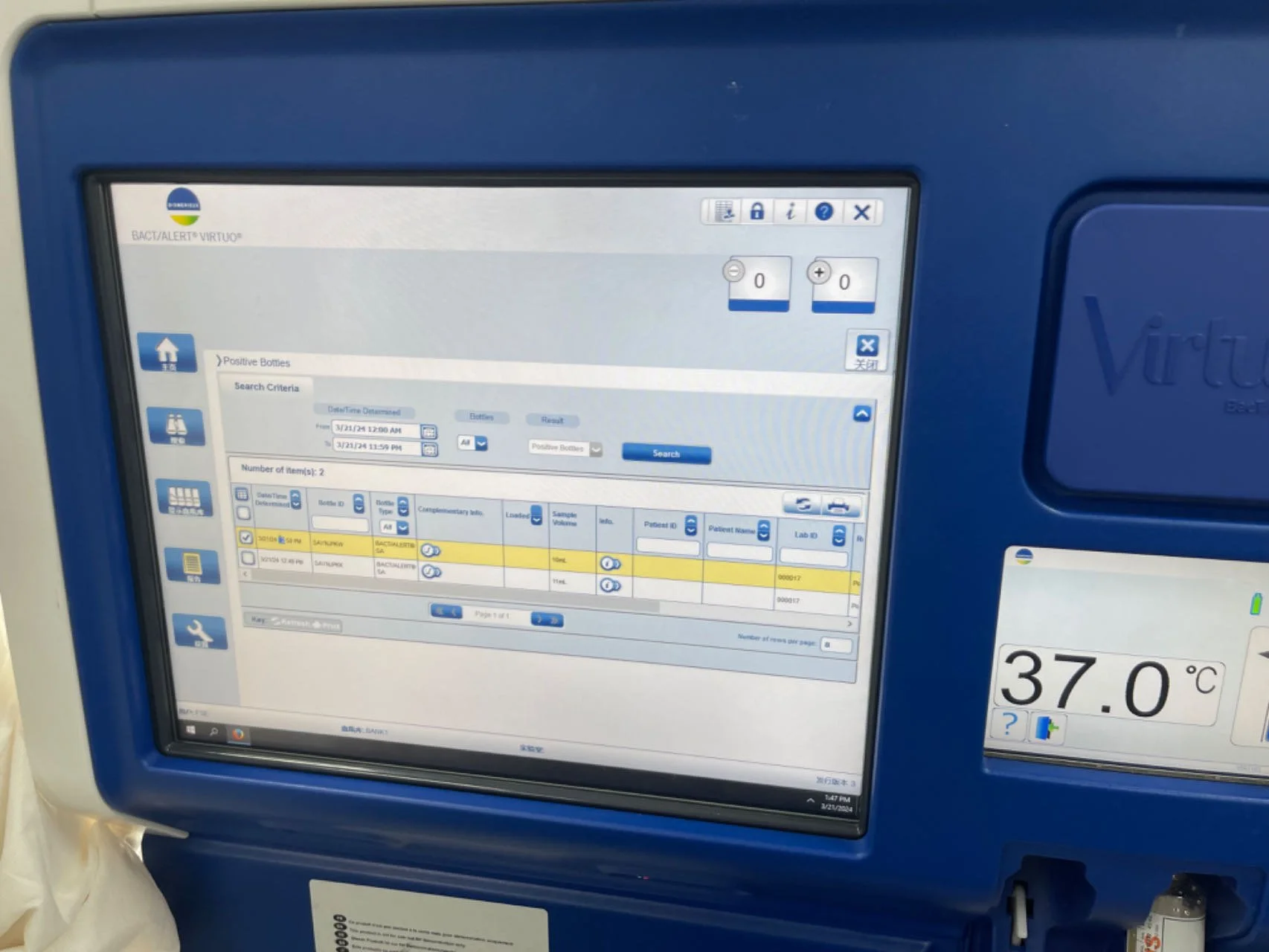

Competitor & Market Analysis

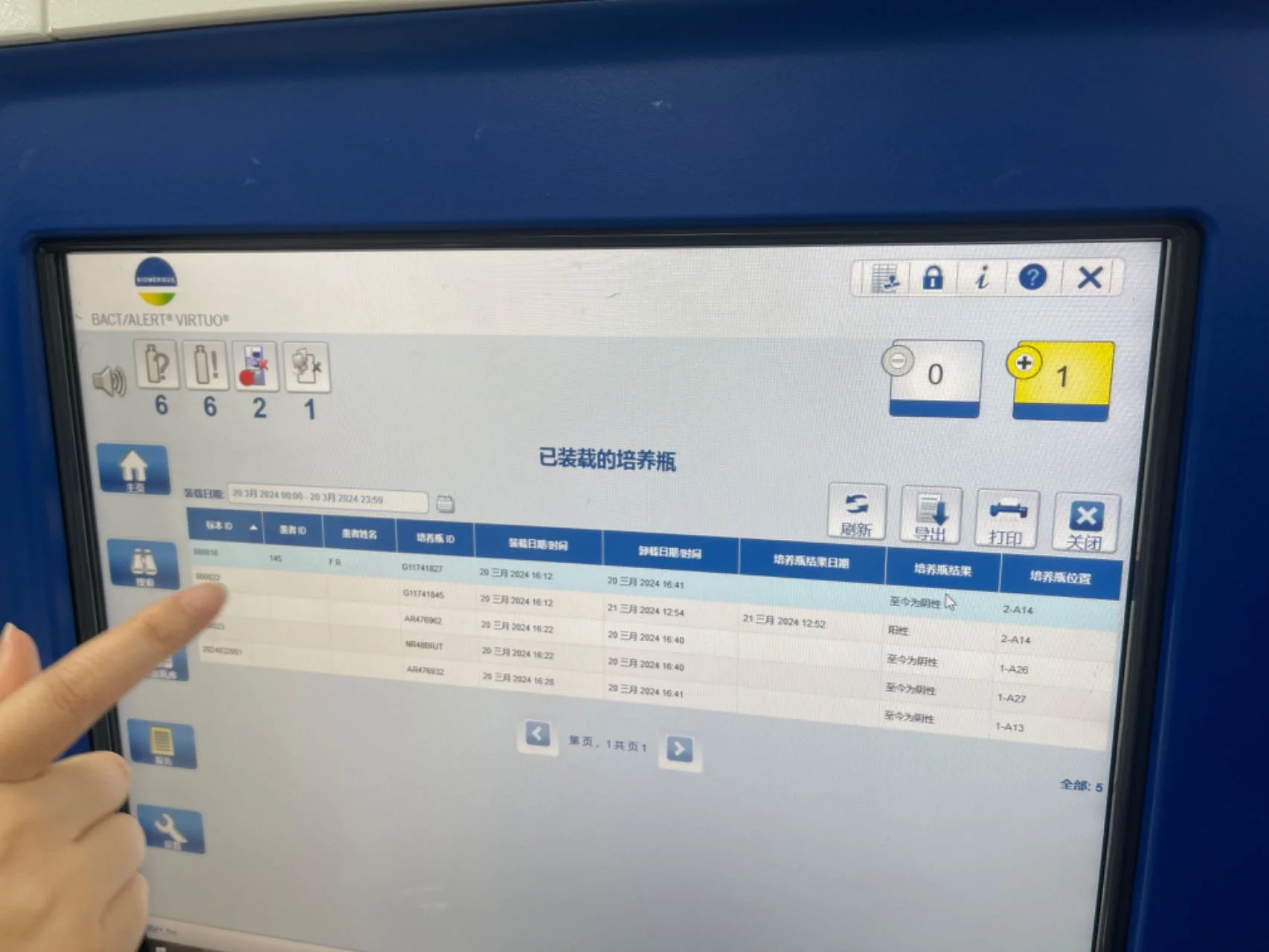

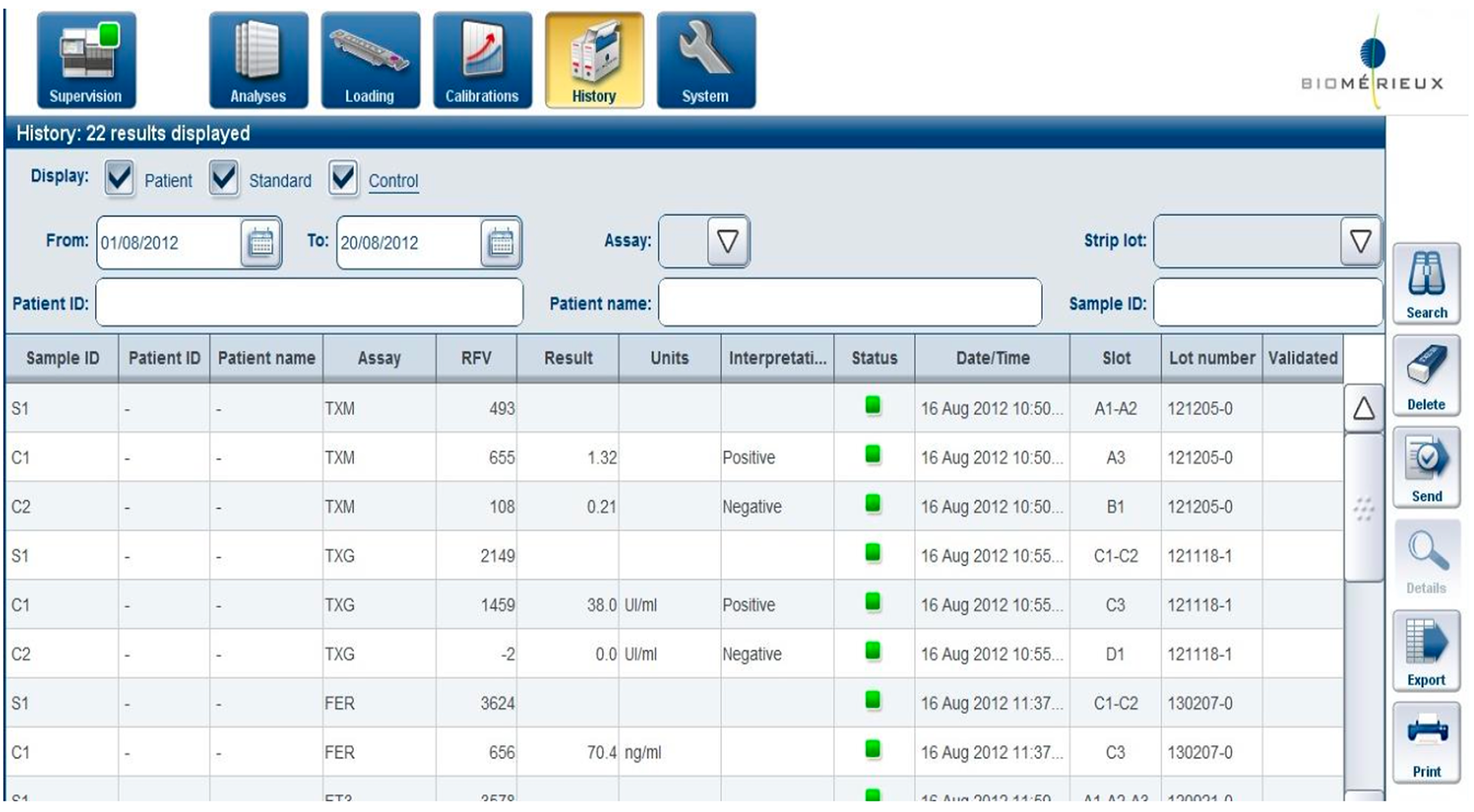

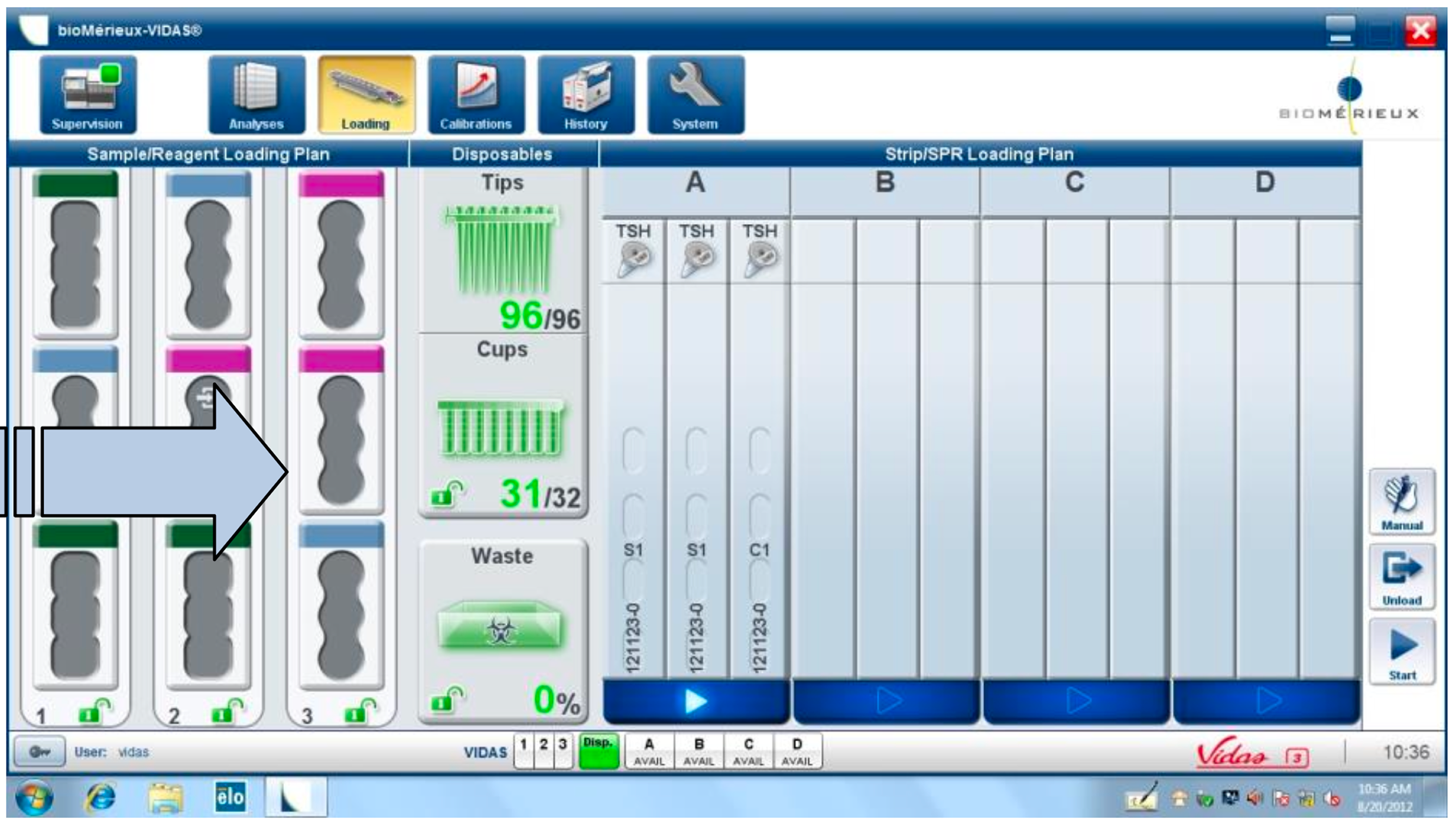

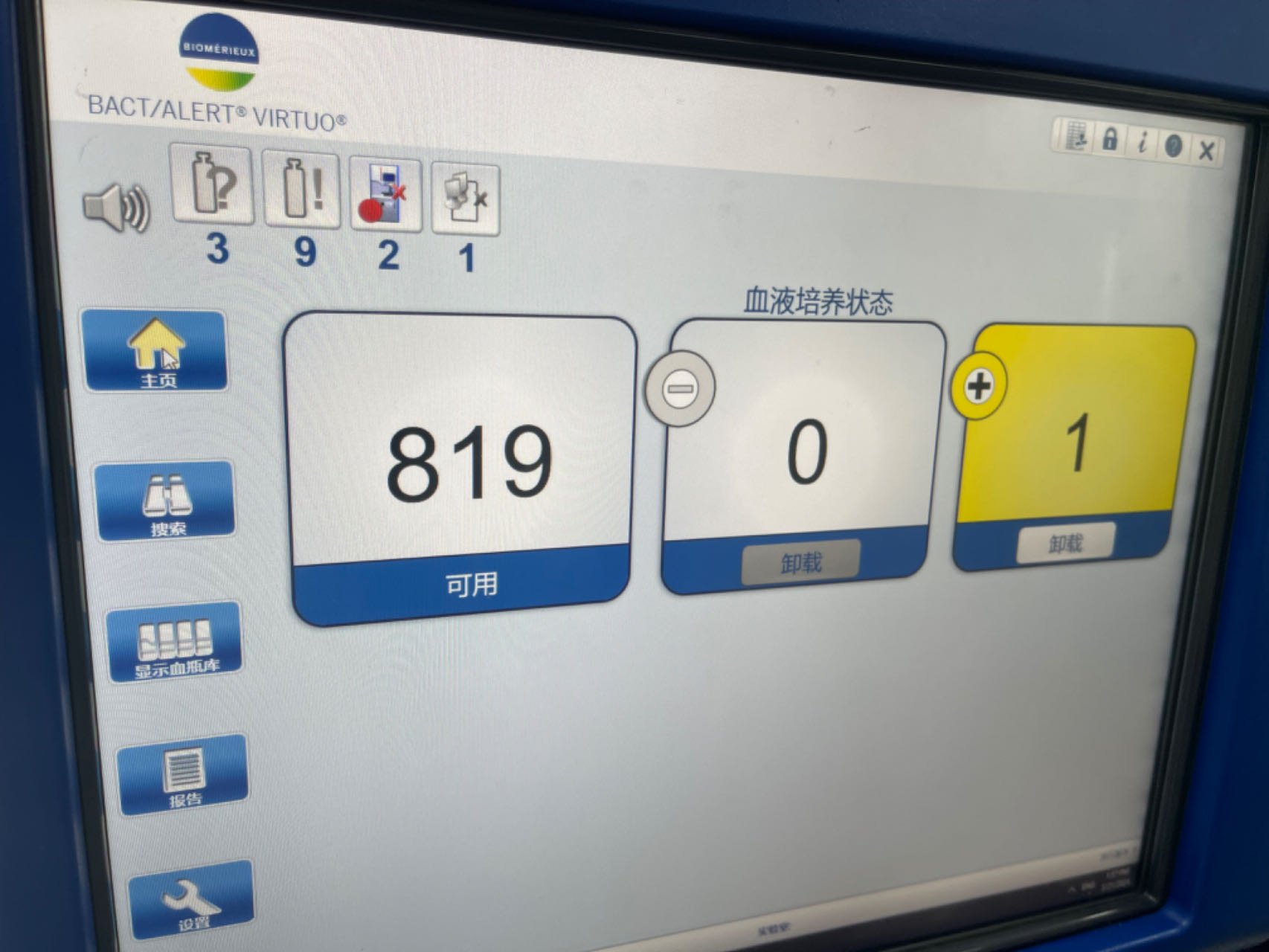

To ground the design in real-world expectations, I conducted hands-on analysis of leading molecular and microbiology diagnostic systems, reviewing both software interfaces and physical interaction models.

Diagnostic Systems Market

Key systems studied:

Cobas e 411 analyzer

BACT/ALERT® VIRTUO®

MAESTRIA V5

What I Evaluated

How users configure tests under time pressure

How systems communicate status, risk, and errors

How software aligns (or misaligns) with physical workflows

How much cognitive load is placed on technicians

Key Findings

Legacy-first interfaces prioritize system logic:

Heavy reliance on tables and modal flows increases error risk

Physical affordances often compensate for poor software

Trust is built through predictability, not only speed

These systems set a high bar for reliability, but a low bar for usability.

Strategic Design Opportunity

This analysis revealed a clear opportunity for Accunome:

Compete on clarity, approachability, and learnability

Reduce training dependency without sacrificing compliance

Treat software + hardware as one unified experience

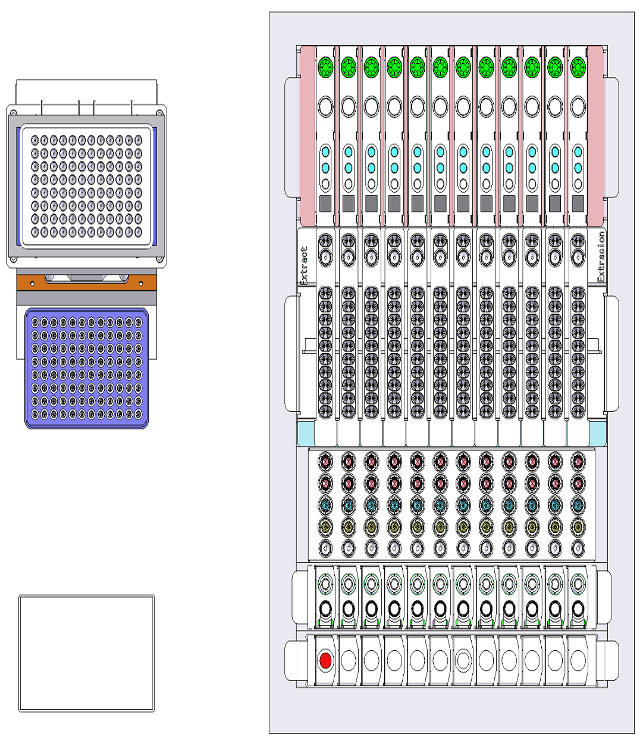

Beyond Software:

the Physical Product

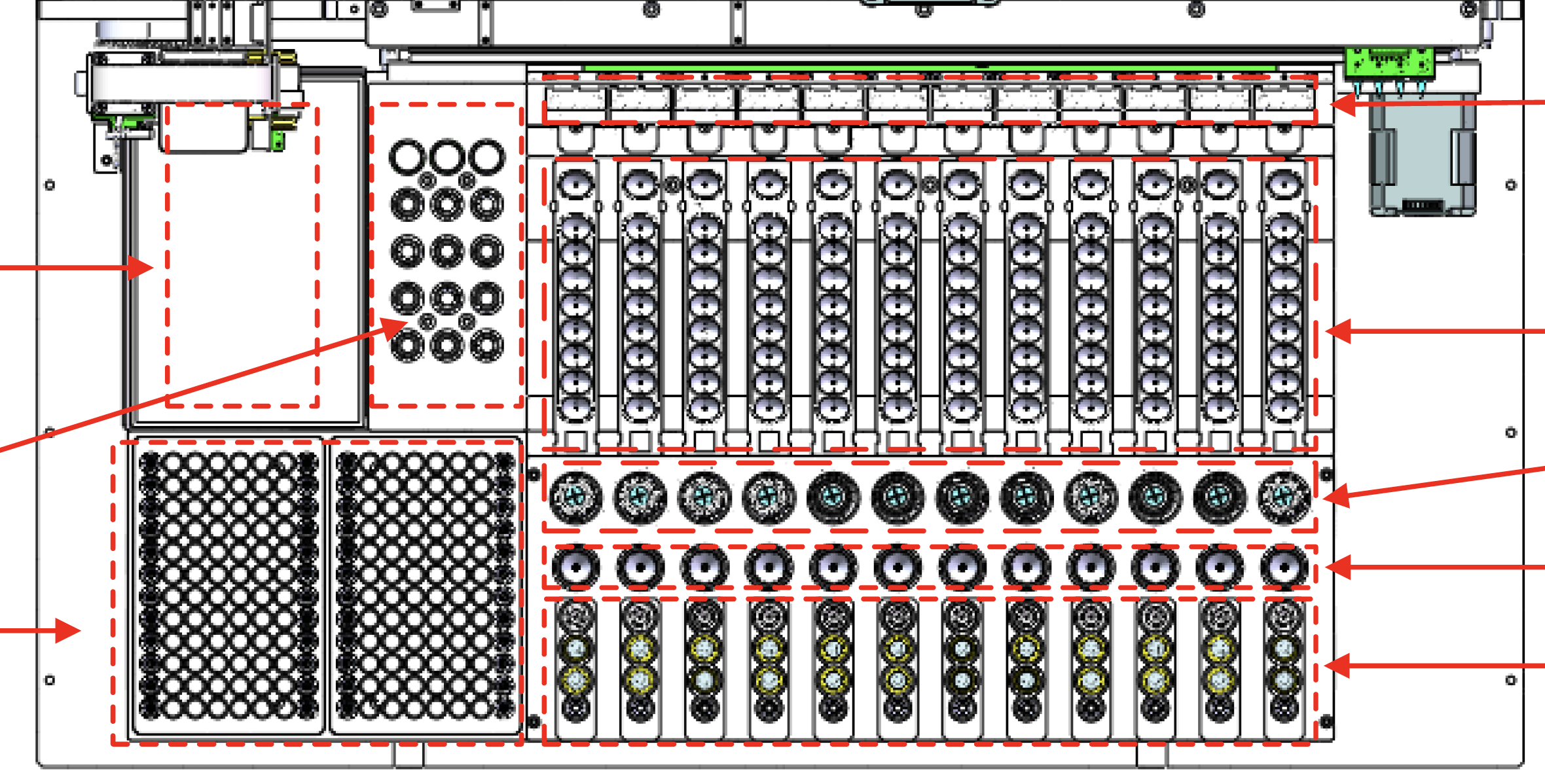

As the DXcellence12 instrument evolved in parallel, I provided UX-driven input beyond the screen:

Sample loading logic and physical-to-digital mapping

Indicator light behaviors and state communication

Alignment between on-device affordances and software terminology

This ensured that the physical machine and digital interface spoke the same language, reinforcing user trust and reducing operational friction.

Key Insights

Labs require both batch efficiency and individual control

Users think in physical wells, not abstract tables

Mixed‑assay batches are common, not edge cases

Trust is built through clarity, predictability, and reversibility

the UI must mirror the mental model of the instrument

What’s Before

Design Principles

Design for Trust — confidence comes from clarity

Visual First — reduce cognitive translation

Flexible by Default — batch + individual coexist

Regulation‑Aware — compliance without burden

Predictable Systems — users know what will happen next

Simplifying Workflow

After reframing the problem, I audited the entire Custom Testing journey. Many steps existed to satisfy system checks rather than user intent.

I deliberately removed or deferred non‑critical interruptions (e.g. trash status, consumables sufficiency) and redesigned the flow:

Reduced 9 linear steps → 6 actionable steps

Ultimately regrouped the experience into 3 cognitive phases:

Setup — define what will run

Confirm — verify consumables and system readiness

Run — execute with confidence

This lowered cognitive load while preserving safety and compliance.

Option & Solution

Exploring Six Input Models

Based on research, I designed six interaction models, each addressing different lab realities and each prototype was designed to be testable, not theoretical:

Manual single entry

Template-based loading

Batch selection

Combo / multiplex combination sets

Historical configuration recall

LIS-driven order import

The Core Breakthrough

The most important decision was to break away from the inherited table‑based UI constraint.

I redesigned Custom Testing around a graphical representation of the physical DXcellence12 instrument:

On‑screen wells map 1:1 to real sample positions

Users interact directly with positions, not abstract rows

What users see on screen matches what they touch on the machine

This removed the need for mental mapping entirely and aligned software behavior with the real‑world mental model of lab work.

Tradeoffs

Designing for Multiple Real‑World Use Cases

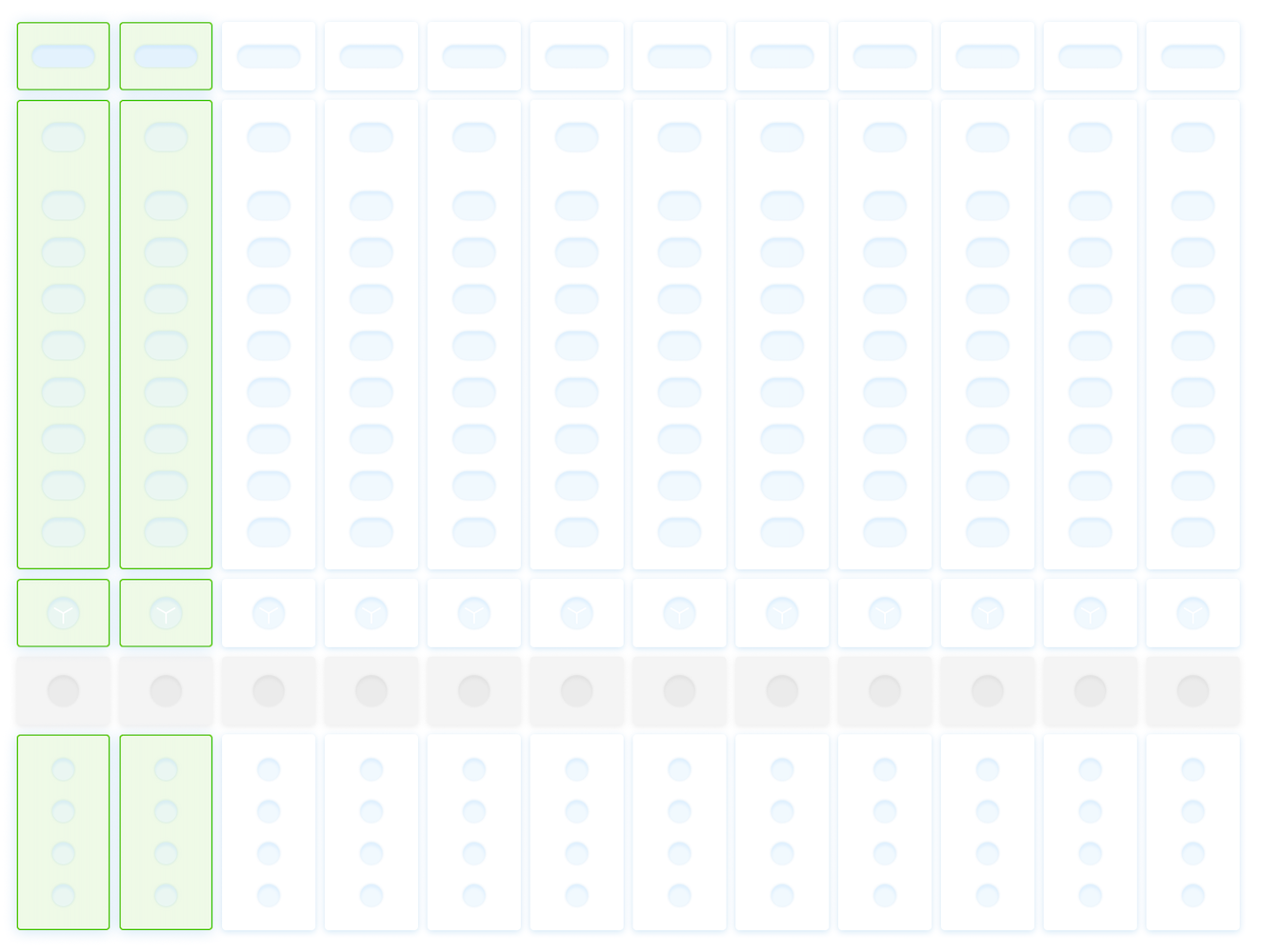

Research showed that a single interaction model could not serve all labs equally. I intentionally designed multiple configuration modes, each optimized for a different operational reality:

Direct input — flexible, per‑run customization

Templates — reusable for high‑throughput running similar tests

Combo — scientist‑preferred common assay groupings

Initially, I believed “Templates” could fully replace “Combo”. Through discussion, challenge, and further validation with scientists and stakeholders, I recognized that “Combo” represents a deeply ingrained expert mental model.

I preserved it as a integrated interaction, signaling respect for domain expertise while keeping the system approachable for new users.

Prototyping & Validation

I built interactive prototypes for each configuration model and tested them with:

Lab technicians and lab managers

Internal product, engineering, and scientific teams

Strategic partner bioMérieux

Testing focused on:

Error prevention under time pressure

Speed vs confidence tradeoffs

Learnability for first‑time users

The final design is not a compromise. It is a deliberate synthesis shaped by real usage, debate, and iteration.

Designing Under Regulatory Constraints

In regulated healthcare software, every major interaction change can trigger regulatory review and approval cycles.

I partnered closely with Product and Regulatory teams to:

Decide which improvements could ship incrementally

Identify when changes justified a bundled submission

Balance speed, safety, and approval timelines

Design decisions were made not just for usability, but for regulatory feasibility and long‑term velocity.

Impact, Outcomes & Reflection

Impact on Users and the Product

This work delivered measurable, real-world impact across multiple dimensions:

User satisfaction increased significantly: lab technicians reported higher confidence, faster setup, and fewer mental handoffs between software and hardware.

Complaints stopped: the previous frustration around the Custom Testing workflow, frequent errors, confusion, and workarounds, was no longer raised after rollout.

Error reduction: the new interaction models aligned with how labs actually think and work, reducing configuration mistakes at the source.

Stronger client trust: key hospital clients and partners gave explicit positive feedback, calling out the clarity and usability of the new experience.

Sales enablement: the improved workflow became easier to demo and explain, directly supporting sales conversations and adoption in enterprise environments.

This was not only a usability improvement.

It materially strengthened product credibility in a regulated, high-stakes domain.

Outcomes on Business

Operational Effectiveness: Reduced test setup time by ~70%, dramatically lowering configuration time and mental burden.

Adoption & Sales Enablement: Significantly increased (internal estimate ~4× growth) product bookings and demo effectiveness.

Played a key design role in Accunome secured a strategic partnership and ~$13.6M investment from bioMérieux

The redesigned workflow and platform achieved CE certification and national Class III NMPA approved regulatory registration.

Reflection: What I Learned

This project reinforced several design principles:

Design leadership starts with initiative: The most meaningful impact often starts with self-directed intent, not assigned scope.

Challenge constraints early: Reframing the problem beyond the pre-set model unlocked every breakthrough that followed.

Design at system level: Lasting outcomes emerge when hardware, software, and workflow are treated as one cohesive whole.